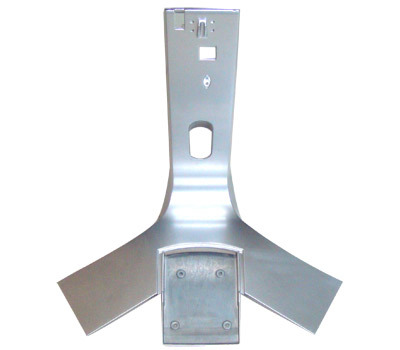

Popular keywords: customized die-casting parts, Shenzhen zinc alloy die-casting mold development, aluminum alloy die-casting, zinc alloy die-casting

Product Show

We implement a seamless link model from product design and development to mass production.

View DetailsWe implement a seamless link model from product design and development to mass production.

View DetailsWe implement a seamless link model from product design and development to mass production.

View DetailsWe implement a seamless link model from product design and development to mass production.

View DetailsABOUT

Acme Metal Products (Shenzhen) Co., Ltd. is a multinational die-casting enterprise headquartered in Chicago, USA, and its parent company is Lovejoy Industries.

It has been engaged in die-casting production and mold manufacturing since 1948, and has its own factories in the United States, China, Brazil, and Portugal. Our core business is aluminum/zinc/magnesium alloy die-casting, and we also provide one-stop procurement services for metal products to global customers.

Acme officially started production and operation in August 2005, committed to providing professional and comprehensive aluminum alloy and zinc alloy die-casting services to global customers.

With extensive industry experience and a professional international engineering team, the company ensures timely and effective technical support and solutions for customers.

Our Advantages

We can truly achieve highly competitive costs, high-quality products, on-time and accurate delivery, and flexible minimum order quantity requirements.

Production Advantages

Strong production capacity, creating high-end aluminum and zinc alloy accessories

1 Buhler die-casting machine, 4 four-axis CNC machining centers, dozens of punching machines, complete mold-making equipment such as grinding machines, milling machines, spark machines, and wire cutting; complete zinc alloy post-processing production line, environmentally friendly polishing workshop, CNC lathe;

Quality Advantages

Strict implementation of product monitoring at every stage

Products have obtained ISO9001, ISO14001 and ISO18001 certifications; Strictly control quality requirements from product mold evaluation, manufacturing process, production process, post-process processing, surface treatment, etc., to improve product quality;

Lean Production

Strong production capacity, creating high-end aluminum and zinc alloy accessories

1 Buhler die-casting machine, 4 four-axis CNC machining centers, dozens of punching machines, complete mold-making equipment such as grinding machines, milling machines, spark machines, and wire cutting; complete zinc alloy post-processing production line, environmentally friendly polishing workshop, CNC lathe;

Professional Technology, Quality Assurance

Provide customers with multi-faceted technical support and thoughtful service

News Center

Company Heyuan expansion activities in November 2024

2024-11-05

The company organized a team-building event in Heyuan for all employees on November 2-3, 2024.

Introduction to Conflict Minerals

2022-03-21

Conflict minerals, also known as 3TG: Tungsten, Tin, Tantalum, and Gold, later added Cobalt, refer to minerals mined under conditions of armed conflict and human rights abuses. Specifically, this refers to resources mined from areas controlled by the Congolese government army and numerous armed rebel groups such as the Democratic Forces for the Liberation of Rwanda (FDLR) and the National Congress for the People's Defence (CNDP) in the eastern provinces of the Democratic Republic of Congo (DRC).

Partners